Description

DESCRIPTION

The Narishige MF2 Microforge replaces and combines the features of the popular MF900 and MF830 models, which have been discontinued. The new MF2 microforge permits the fabrication of glass tools and fire-polishing of micropipettes under microscope visualisation. As with the MF900, the new MF2 offers a wide range of functions including the ability to cut, bend, fire-polish, form a spike or manufacture of a variety of micro-tools from glass pipettes. Note that eyepiece/objective lenses are sold separately, so it is necessary to select the most appropriate lens set for your needs (see here and below).

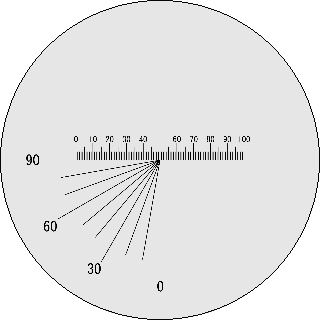

The MF2’s microscope is compact, yet robust, reducing the risk of pipettes breaking during handling. All fine controls are accessible via precision knobs installed on the microscope and the focus control can be switched to the left side of the microscope if preferred. The MF2 provides a heater-level readout, which is essential for such precision work. The heater is turned on and off with the included foot-switch. A new LED light source provide glare free illumination with variable brightness control.

An easy-to-use manipulator is provided for operating the heater and pipette, and the microscope is operated three-dimensionally with control close to the operator’s hand. Separate rotation mechanisms for vertical and horizontal movement allow the pipette to be approached at any angle, while a special device in the heater section can form it into any required shape.

Improvements over previous models:

- XY Control Unit is Stabilised – The XY control unit is now locked and does not feature the “sprung-return” feature of older models.

- New Digital Display – Heater settings are easier to see or adjust and a “Burnt” warning alerts the using to a broken filament.

- New LED Lamp Reduces Eyestrain – The new LED lamp has a wider range of brightness, presenting less glare to the operator.

- Easier Wire Replacement – Spring-loaded clips enhance the user’s ability to replace the Platinum wire.

Optional Lenses, Eyepieces & Lens Sets (Sold Separately)

Lens Set 1 includes eyepieces and two objectives for total magnifications of 50x and 100x. For higher magnification applications, such as fire-polishing of patch pipettes for electrophysiology, we recommend the MF2-LE15 eyepiece set and the MF2-LO40 40x Objective Lens, providing 600x magnification.

| Model | Product | Magnifications in total | Objective Lens | Eyepiece | Application |

|---|---|---|---|---|---|

| MF2-LS1 | Lens set 50x/100x | 50x/100x | 5x, 10x | 10x 10x with micrometer |

For microinjection pipettes |

| MF2-LO40 | 40x Objective lens | – | 40x | – | – |

| MF2-LE15 | 15x Eyepiece set | – | – | 15x 15x with micrometer |

– |

Specification

| Accessories included | Foot switch Power cord Pipette holder Hex wrench Spare heater (PT-B) Silicone rubber gasket (HI01PK01) |

|

|---|---|---|

| Movement range | Heater manipulator | X14mm, Y14mm, Z14mm |

| Pipette manipulator | X12mm, Z28mm | |

| Microscope | Y (Focus-Coarse/Fine coaxial knob) 30mm X (Swing-Fine control knob) approx. 5° Z (Tilt-Fine control knob) approx. 3° |

|

| Magnifications | 50x/100x (optional lens MF2-LS1: eyepiece 10x, objective lens 5x/10x) 600x (optional objective lens MF2-LO40 40x and eyepiece 15x) |

|

| Glass capillary * | ø1mm, ø1.2mm, ø1.5mm | |

| Working voltage | AC100V ~ 240V, 50/60Hz | |

| Power consumption | 13W | |

| Dimensions/Weight | W210 × D300 × H280mm, 5.8kg | |