Micromanipulators

Choosing suitable equipment for your application

New to the world of electrophysiological micromanipulation?

Selecting the right equipment can sometimes be overwhelming.

All micromanipulators are designed to scale down the movement of a human hand. But this can be achieved in several ways and there are many different models to choose from. As a beginner, it can be difficult to make sense of the options and determine the best choice for your application.

Here at Digitimer, we supply the full manipulator range by Narishige – one of world’s leading manufacturers within the micromanipulation market – and we have excellent knowledge in this area.

To make your purchase decision a little easier, here our in-house specialists explore the fundamental characteristics of micromanipulators and outline the key factors you need to consider.

Read on to learn more and, if you have any questions, feel free to call us on +44(0)1707 328347.

4 factors to consider when buying a Narishige micromanipulator

1. Type of drive

Narishige micromanipulators fall into three categories according to their drive mechanisms (i.e. what controls their movement): direct drive (manual), motor drive and hydraulic drive.

- Manual micromanipulators

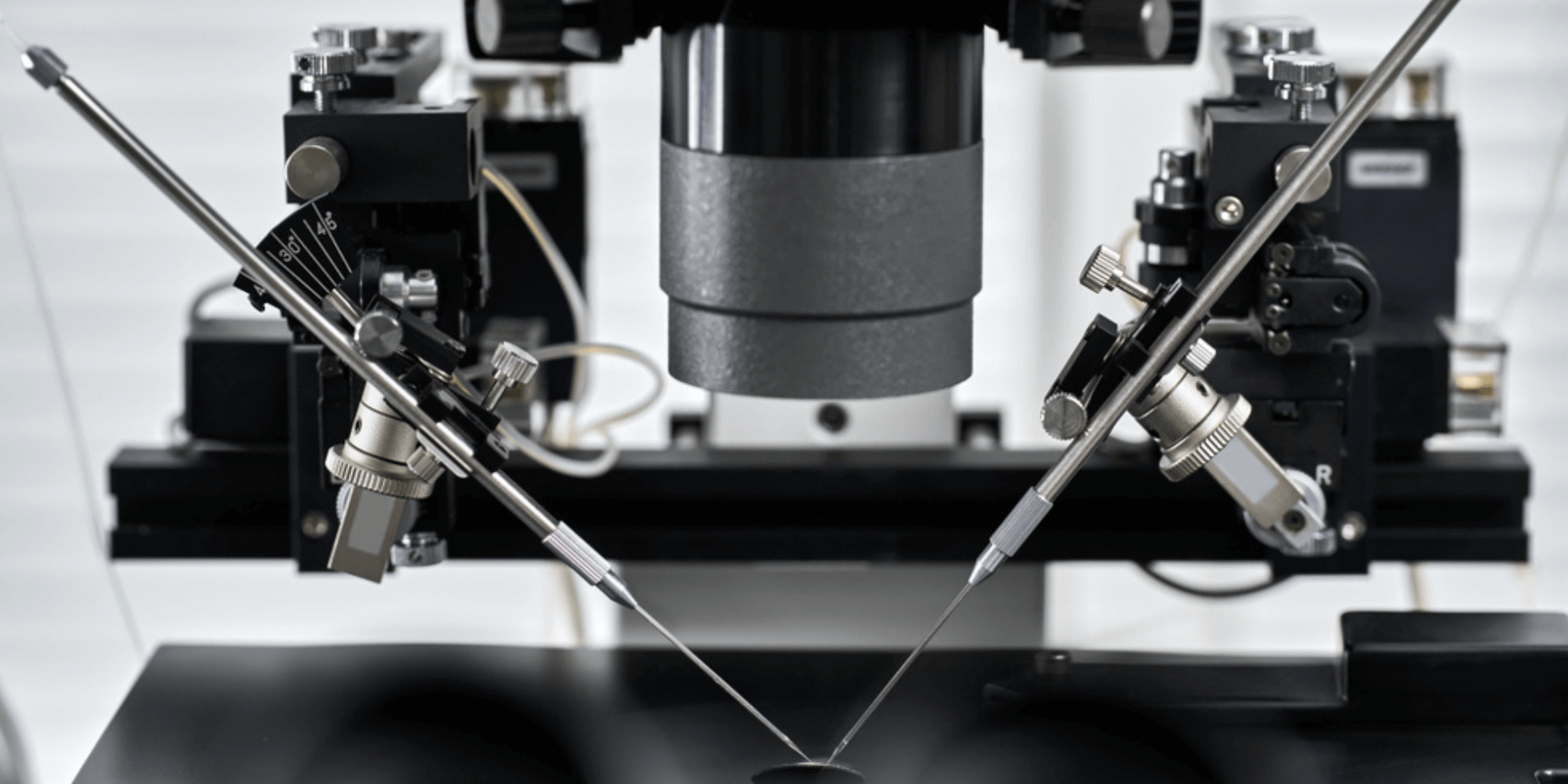

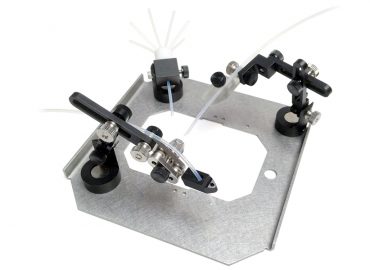

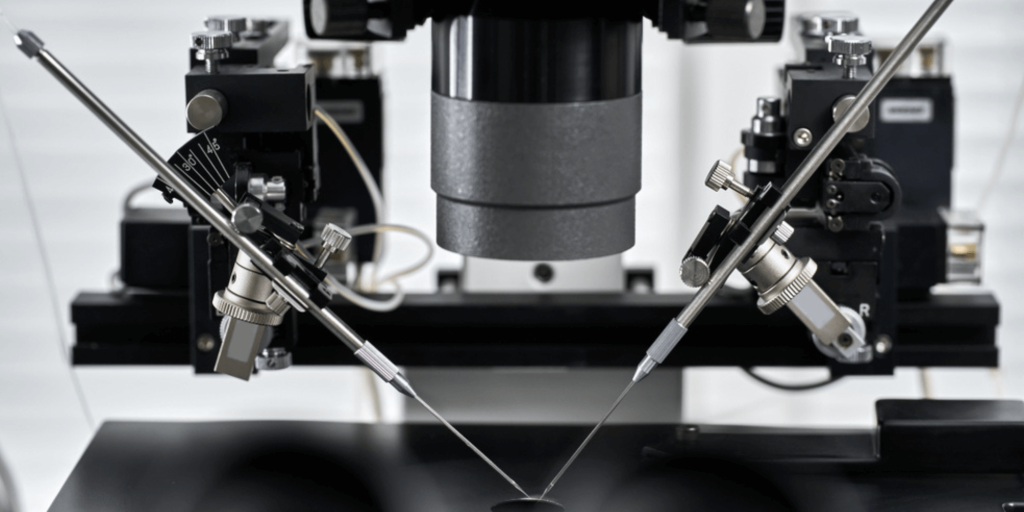

Manual micromanipulators (aka mechanical micromanipulators) use mechanical gears or cantilevers to reduce macroscopic movements into microscopic movements.

Some are controlled by hand using knobs for fine and coarse movements. These are particularly useful for applications that require precision and stability (such as electrophysiological recordings including patch-clamping), as once you reach the desired location, the knob will remain in position.

Others are controlled by a joystick. Mimicking the movement of the hand, these allow velocity and acceleration to be replicated – making them a suitable choice for microinjection experiments.

- Motorised micromanipulators

These use a very similar gear system to manual micromanipulators. However, instead of being driven directly by hand, motorised micromanipulators are driven by electrical motors.

Operated using a joystick or remote control, they facilitate high precision movement on a variety of axes – and are a great option for applications where consistency and reproducibility are important.

- Hydraulic micromanipulators

Narishige hydraulic micromanipulators rely solely on the movement of a hydraulic fluid (i.e. water or oil).

To scale down the movements of a human hand, this hydraulic fluid is transferred between cylinders of smaller diameters to cylinders of larger diameters. And this type of micromanipulator tends to be operated via a remote control, meaning there’s much less chance of creating vibrations or torque.

2. Movement axes

Whether it’s a manual model, motorised or hydraulic, a micromanipulator can have one or several axes of movement. These are generally described as X,Y and Z – which translates to horizontal movement (right/left), vertical movement (up/down) and backwards and forwards, respectively.

The ideal range of movement for you will depend on the specifics of your experiment.

For example, are your samples stationary (i.e. a neuron for patch clamp) or can they move (i.e. cells in suspension)? Will the micromanipulator be used to hold and move a needle holder, or to move materials around? Do you need it to move very far or on a relatively small scale?

3. Movement ranges

Narishige micromanipulators can also be split into two groups based on their movement range:

- Fine micromanipulators

As the name suggest, these are ideal for very small, precise movements. Fine movement micromanipulators permit operation in the nanometre (nm) to micrometre (µm) ranges. And a full rotation (via the knob, joystick etc.) will typically shift the tool by 100µm.

- Coarse micromanipulators

Coarse movement micromanipulators are better suited to larger, crude movements. Movement is typically graduated in millimetres (mm). And a full rotation might move the tool by 18mm.

Whilst most micromanipulators are dedicated to either fine or coarse movements, some combine both – allowing the researcher to control both smaller and larger movements with just one device.

4. Unwanted movement

There’s no such thing as a micromanipulator that holds instruments perfectly still.

However, to help minimise any unwanted movements and promote stability as much as possible, it’s worth choosing a device that offers both drift and backlash control (i.e. movement of the instrument that wasn’t intended and unwanted movement at the end of the intended movement).

If stability is particularly important to your experiment (e.g. for electrophysiological patch-clamp recordings), a manual micromanipulator may not be the best option. As these are controlled by hand and operated via touch, the chance of inducing vibrations and creating torque is relatively high.

In such circumstances, a hydraulic device – particularly one that uses water – will be more suitable.

Narishige also offer a collection of anti-vibration equipment, which provide a stable platform and can help to reduce the impact of vibrations when performing vibration-sensitive techniques.

Need help choosing a micromanipulator?

It can be a difficult choice, and one that’s important to get right – so it’s certainly worth doing a little research into the options available before committing to a purchase.

Detailed information on our complete range of Narishige micromanipulators – including manual, motorised and hydraulic models – can be found in the brand’s product catalogue.

You’re also welcome to contact our specialist team, here at Digitimer, at any time.

Thanks to our long-standing partnership with Narishige, we have excellent knowledge of their full range of micromanipulators and precision instruments. We’re always happy to help and will gladly talk you through the features of each, offering advice on the best options to meet your needs. Either give us a call on +44 (0)1707 328347 or send an email to [email protected].

If you have an idea of which products might be best, you can also request a quote with details of how you intend to use the equipment. A member of the team will then respond as soon as possible with application-specific recommendations and an estimated price for your order.